Welcome to JNJ Group Services

JNJ Group Services is committed to providing the highest quality electric, plumbing and allied services to key Government, Infrastructure and public facilities in Victoria. Our core philosophy is to offer a style of service that gives our clients the confidence and surety that the job will be done to the highest standard, on time, every time while safeguarding vital assets.

Sectors We Serve

Healthcare and emergency services

Hospitals, Fire, Police, Ambulance, Aged Care, Defence

Public Infrastructure

Public Transport, Communications, Delivery Services, Cultural and Entertainment Venues

Community – Utilised Commercial

Banking, Petroleum, Shopping Centers

Projects

Museum Victoria

Museum Victoria

Routine Maintenance

When JNJ Electrics won Museum Victoria’s (MV) Electrical Maintenance contract for Melbourne Museum in 2016, we also accepted the maintenance of the Royal Exhibition Buildings, Scienceworks & the Immigration Museum. JNJ immediately set up a transition process and performed an Electrical Audit on the each site to determine the condition and level of compliance of the extensive portfolio of assets.

JNJ worked closely with MV to set initial Priorities for testing and servicing the Air Circuit Breakers, Fuse Switches and Transfer Switches, including thermal scanning of each high current connection point. To minimise impact with the public, significant effort was put into scheduling works around the open hours across each of the facilities. Maintaining MV’s ESM compliance has also been a targeted priority and JNJ’s attention to detail and sophisticated documentation system ensured that MV always has access to current asset maintenance data.

Through working closely with the various Facilities and Project staff and from the extensive site knowledge gained by JNJ during the maintenance contract, MV now look to JNJ Electrics to provide recommendations and strategies to improve the lifespan, reliability and efficiency of their Electrical Installations.

Chadstone Shopping Centre

Chadstone Shopping Centre

Routine Maintenance

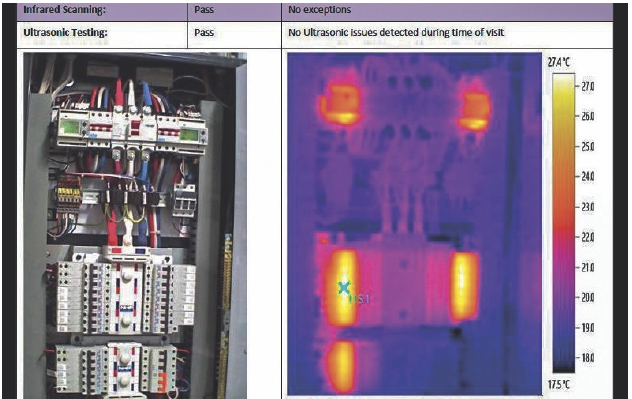

JNJ Electrics recently audited, analysed and carried out certified preventative maintenance for Vicinity Centres across the electrical low voltage distribution assets throughout the Chadstone Shopping Centre. Thermal scanning and ultrasonic testing was carried out to switchboards and other distribution assets, resulting in a 750 page audit and test summary report.

The report contained critical asset information, operational ratings and photographs of each asset, thermal images, future maintenance recommendations and a summary of identified issues, including priority ratings and references to the applicable Australian Standards for each identified defect.

The Building’s Operations Manager was notably impressed with JNJ’s quality of work, adherence to the Centre’s procedures and the high level of communication that was provided to schedule the works and co-ordinate access to each location.

St. Vincent’s Hospital Fire Rescue Victoria (FRV) Warringal Private Hospital

St. Vincent’s Hospital Fire Rescue Victoria (FRV) Warringal Private Hospital

Routine and Reactive Maintenance Contracts

Essential routine and reactive maintenance works have been core services delivered by JNJ to our clients for over 25 years.

The reliability and surety of the plumbing services we deliver are hallmarks that JNJ are widely known for.

Our Routine and Reactive Maintenance Contracts cover many vital areas of the licensed Plumbing trade, including:

• Preventative Maintenance Inspections

• Backflow Prevention and Thermostatic Mixing Valve testing

• 5 yearly Thermostatic Valve element replacement program

• Hot water system service, repair and replacement works

• Solar Hot Water systems

• Rainwater Harvesting systems

• Stormwater Drain inspection & repair works

• Roof and Gutter inspections and repairs

• Emergency Plumbing attendances and repairs

• Minor installation and upgrade works

• Standardizing fixtures & tapware

JNJ work closely with our clients to understand their priorities, systems & culture, all of which are crucially important factors for successfully delivering essential routine & reactive maintenance services within their dynamic work environments.

Our industry knowledge, reliability, value for money, and commitment to our client’s best interest ensures that JNJ Plumbing remains a preferred Contractor to proficiently and dependably deliver plumbing services to their critical facilities.

Dynon Freight Terminal

Dynon Freight Terminal

Capital Works

The level of yard lighting at this vital freight terminal was found to be well below the required standard, reducing both site safety and productivity around the yard. Providing a design solution to improve the lighting produced from these 35 metre high towers presented a number of challenges, particularly considering the large footprint and constantly busy nature of the site.

Coolon partnered with JNJ Electrics to provide a high efficiency maintenance free design solution using 36x 480w Industrial rated LED Flood Lights to replace the existing 48x 1000w HPS fittings. JNJ worked closely with Victrack to co-ordinate a suitable installation window and a strict timeline and works program was created to ensure the works rolled out according to plan. The JNJ team brought in a massive 55m boom lift to replace the fittings and a closely co-ordinated effort with the Coolon team ensured that the results accurately reflected the design. Once the commissioning phase had been completed, and measurements were taken across the site, it was confirmed that there was an average increase in light levels of over 400% and a reduction in annual operational costs of 82%. Both Victrack and the site tenant were amazed by the difference this lighting solution had provided to the site and greatly appreciated the results that both Coolon & JNJ Electrics was able to produce with minimal disruption to regular site activities.

Victorian Emergency Services Organisation

Victorian Emergency Services Organisation

Trade Waste Tank Cleaning & Inspection

The Craigieburn Emergency Services Training Centre uses a 30,000 litre below ground trade waste effluent tank, to recycle fire fighting water & associated foam products.

The task was to pump out, clean, and inspect this tank, which is a Confined Space, with the work being classified as High-Risk.

A detailed Safe Work Method Statement (SWMS) was created to identify risks & hazards, with suitable strategies adopted to ensure work could proceed safely. The safety measures included:

• air quality monitoring equipment to be used;

• breathing apparatus to be worn by anyone entering the tank;

• Standby Rescue personnel and equipment;

• retrieval tripod, winch, & full body harness;

• Isolation of the tank for the duration of the job;

• warning signage and work area delineation measures.

Once the tank had been pumped out and cleaned with a high pressure washer, the waste was removed from site and disposed of to EPA requirements, with a Certificate of Disposal issued.

An internal inspection was undertaken of all surfaces, seams and joints. Photos were taken throughout the inspection process.

The tanks integrity was assessed and determined as being in sound operable condition with no requirement for internal repair.

The Tank was returned to active service and a detailed condition report was issued to the Training Centre ‘s Facilities Manager who expressed their appreciation for our attention to detail and adherence to our documented safety processes.

Various Clients

Various Clients

Backflow Device Testing & Servicing

JNJ Plumbing undertakes annual testing and servicing of Backflow Prevention Devices to keep these valves in good working order so that they can continue to safeguard the public water supply and protect our valued client’s facilities . This important routine maintenance function is required to be performed by an Accredited Practitioner in accordance with AS3500.1992 and AS2845.3:1993 Standards.

JNJ’s Accredited Plumber tests Backflow Prevention devices by turning off the downstream shutoff valve and connecting a specialized Backflow testing kit to pressure test the valve’s operation. If the valve operates correctly, we immediately return supply to the site. If it doesn’t pass the required pressure test, we repair or replace the faulty valve, and retest the repaired Backflow prevention system to verify it’s compliant operation.

Once the testing work has been completed, JNJ’s Plumber provides a test report to our client and lodges it on-line with the relevant water authority. These measures ensure the site remains compliant to the mandatory testing and reporting provisions for Containment Backflow prevention devices.

As many of JNJ Plumbing’s clients operate busy Emergency Service facilities such as FRV, Hospitals, Ambulance Victoria, etc, our approach to these testing works is to schedule suitable times around our client’s requirements to ensure they can maintain an uninterrupted water supply to their critical services

Contact Us